x

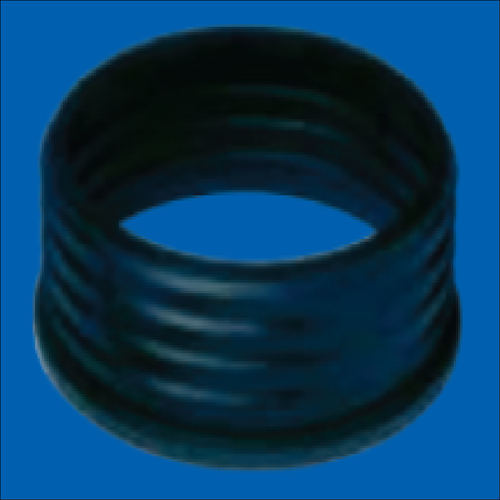

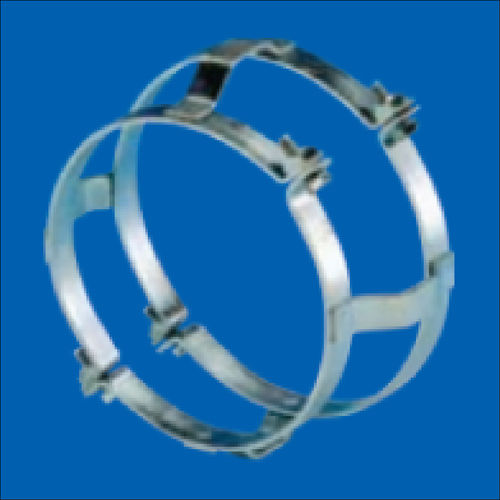

Compensator Coupler

115.00 - 150.00 INR

Product Details:

- Application Pipeline Swivel Connections

- End Protector Plastic Cap

- Tolerance 0.5 mm

- Product Type Compensator Coupler

- Type Rotary

- Shape Cylindrical

- Connection Welded

- Click to View more

X

Compensator Coupler Price And Quantity

- 1000 Piece

- 115.00 - 150.00 INR

Compensator Coupler Product Specifications

- 100 mm

- Metallic Silver

- 250 mm

- 0.5 mm

- Welded

- DIN / ANSI

- 8 mm

- Cylindrical

- Pipeline Swivel Connections

- Compensator Coupler

- Rotary

- Plastic Cap

Compensator Coupler Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 5000 Piece Per Week

- 7 Days

- Western Europe, Australia, Eastern Europe, Middle East, Africa, South America, Asia, Central America, North America

- All India

Product Description

Since the establishment year, we are offering premium quality Compensator Coupler. We provide this coupler in various shapes, sizes and can also be custom designed for fulfilling the specific needs our precious clients. The provided coupler is manufactured by making use of optimum grade materials and modern techniques under the supervision of our skilled team of experts. With powder coated finish and sturdy structure, this Compensator Coupler is highly acclaimed for fitting purpose and can be availed at marginal prices from us.Features:

- Easy to install

- Sturdy design

- Dimensionally accurate

High-Performance Construction

Manufactured using advanced forging and machining processes, this compensator coupler features high tensile carbon steel for superior strength. Its anti-corrosive surface finish ensures resistance to harsh environments and oxidizing agents, making it suitable for long-term industrial operations.

Versatile Pipeline Applications

Specifically designed for swivel connections in pipelines, this coupler accommodates a range of fluids including water, gas, and oil. Its robust welded rotary construction and precise dimensions, certified to DIN/ANSI standards, guarantee safe and reliable performance across multiple sectors.

Quality Assurance and Handling

Each unit is packaged in a sturdy wooden crate, with plastic caps protecting the ends during transportation. The strict adherence to 0.5 mm tolerance and thorough surface treatment minimize the risk of damage or leakage, guaranteeing quality delivery from manufacturer to end-user.

FAQs of Compensator Coupler:

Q: How is the compensator coupler installed within pipeline systems?

A: The coupler is designed with a welded connection, enabling secure integration into pipeline systems. It is essential that the surface is properly prepared and aligned before welding to meet the required DIN or ANSI standards and ensure leak-free performance.Q: What processes are involved in manufacturing this compensator coupler?

A: Production involves forging high tensile carbon steel, followed by precise machining to achieve stringent tolerances (0.5 mm). The product undergoes surface finishingeither galvanizing or anti-corrosive coatingto enhance resistance to environmental factors.Q: When should this compensator coupler be used in an industrial setting?

A: This coupler is particularly suited for scenarios demanding high durability, temperature fluctuations between -20C to +200C, and a pressure rating up to PN16/Class 150. It is ideal for critical pipeline swivel connections in facilities managing water, gas, or oil.Q: Where is this compensator coupler typically applied?

A: The product is commonly used in water, gas, and oil pipeline systems across industrial setups, both domestically and internationally, thanks to its compatibility with DIN and ANSI standards and robust design.Q: What materials and finishes help this coupler resist corrosion?

A: Constructed from high tensile carbon steel, the coupler is finished with galvanized or specially formulated anti-corrosive coatings, ensuring excellent resistance to oxidation, rust, and other corrosive elements encountered in various pipeline environments.Q: How does the design benefit pipeline operations?

A: Its rotary, cylindrical design accommodates movement and misalignment, helping to reduce stress on adjoining pipes and mitigate leakage risk, thereby enhancing the overall reliability and lifespan of industrial pipeline systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Astral Silencio' category

|

ASTRAL POLY TECHNIK LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |